Rehabilitating the Centerboard

No more LEEWAY!!

Introduction

I sail on the Chesapeake Bay and its tributaries. The average depth of the Bay is 18

feet. Part of the reason I bought Pelago is that her draft is only 4'6" with her centerboard up.

The problem is that the centerboard doesn't work. Charlie, the previous owner, told me he was told that, "The board hasn't been down in 20 years." The likely problem is that marine growth has blocked the board and continues to grow in the well.

The other problem is that the board is hydraulically controlled and the system is in bad shape. The system consists of three cylinders that live in the bilge.

| The three cylinders live in the bilge and contract to pull the board up. |

| The rods were not retracted all the way so they are badly rusted. The brackets that hold the cylinders and sheaves are very badly rusted. The pump is missing.

|

| The upper bilge. The silver rod goes through a packing into the centerboard well. A cable connects the rod to the board. |

| Close up of cylinders and piston rods. |

| This bracket anchors the end of the hydraulic cylinders. Notice the big piece of rust that flaked off. |

| This is the forward bracket that holds the sheave and the turnbuckle. |

| The board moves! Eric and Ned Tyler celebrate. |

| Cranking the board down with the puller.

|

| The top of the board is loose and ready to lower. |

| Pelago's centerboard exhumed.

|

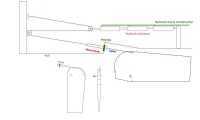

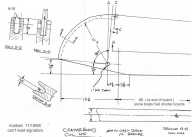

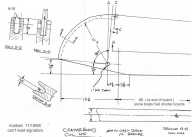

| Most of a scan of the C-40 centerboard engineering drawing.

|

Eric White, Spring 2003

Return to the Pelago Pages